UH Scientists Say the Technology Offers Real Value, at Fraction of the Cost

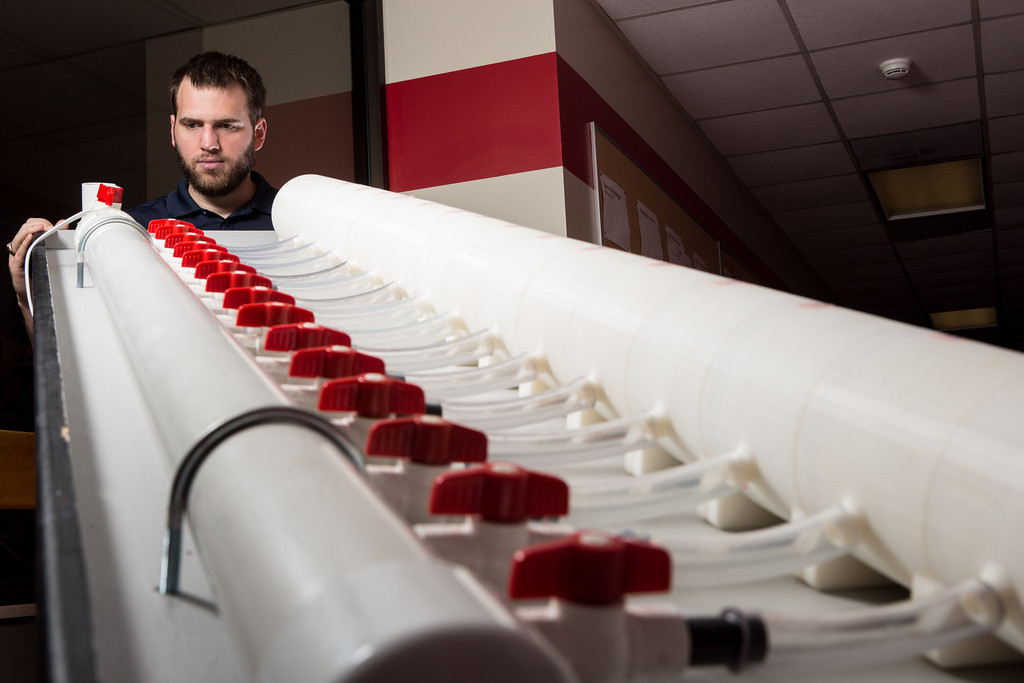

Drew Russey with 3D-printed wind tunnel used in fruit fly study.They don’t look much different from any other piece of office equipment, but 3D printers are transforming university teaching and research.

“If you can think of it, you can print it,” said Tony Frankino, assistant professor of biology in the College of Natural Sciences and Mathematics at the University of Houston.

The concept of 3D printing has been around since the 1980s, but advances in the technology – along with reduced costs – have made the printers more practical for everyday use in academia.

A number of UH researchers have added 3D printers to their labs over the past few years. The College of Optometry installed one in 2003, and the number has grown steadily since.

The printers are most often used to illustrate complex concepts in the classroom, but a handful of academics have begun to use them to facilitate their research. While plastic is the most common medium, Frankino said some printers can produce designs in metals, ceramics and even biological tissues.

He used one of the printers installed in the Information Technology Center at the College of Natural Sciences and Mathematics to build a series of small wind tunnels that one of his Ph.D. students, Drew Russey, used to study fruit flies and their ability to adapt to new environments. Frankino also used the printer to make smaller scale models of the wind tunnels to take to conferences and lectures, a visual aid to explain the research.

For now, many researchers say the printers’ greatest value is in creating models of complex concepts, both to help explain their research and as a teaching tool in their classrooms.

Ognjen Miljanic with 3D-printed models illustrating concepts in chemistry.Chemist Ognjen Miljanic began using a 3D printer several years ago to illustrate some of the concepts his graduate classes were discussing.

He also has printed out models of his own work – the crystal molecules he works with are far too tiny for visitors to the lab to see, and the 3D models are great for presentations.

“For us, the impact on research, it’s not quite there yet,” he said. “The impact on teaching, it’s dramatic.”

Miljanic included a proposal involving 3D printing when he applied to the Cottrell Scholars program, an honor awarded by the Research Corporation for Science Advancement – creating a database of plans for 3D models geared to widely taught advanced chemistry classes, allowing faculty members anywhere to print the models at their own institutions.

That wasn’t the only thing in his proposal – he was awarded one of 13 spots in 2013 – but he said it drew the most attention.

“The cost has dropped over the last 10 years,” he said. “The barrier now is that many people are uncomfortable trying to prepare a 3D model design.”

The value to students is obvious, Miljanic said.

“I realized that models could convey some concepts much better than I could in two dimensions on the board.”

The savings is not just financial. Frankino estimated that designing a wind tunnel like the one used in Russey’s research could have taken a year and $60,000 to have manufactured elsewhere.

Making it via 3D printing took two weeks and cost $2,000.

“That’s pretty science fiction to me,” he said. “That’s amazing.”

- Excerpted from UH news article written by Jeannie Kever, University Communication